New:

Dewatering drum

|

Features: Efficient dewatering Low wear and tear Low energy usage Low investment cost Quiet operation, no vibration |

| drum with optional oversize separator, 400 t/h |

Dredging and mineral processing often is often accompanied by a dewatering problem. The most common machines for this are screens, dewatering wheels, screws, cyclones or simply settling ponds. Another, real alternative is Pressair's dewatering drum. The most suitable system must be defined case by case, considering both, technical end economic aspects.

With more than 35 years practical experience of different dewatering systems, Pressair has great expertise in this field. There is no tougher bench test than a dredge, and over the years Pressair's dewatering drum DD-20 has proved to be an excellent tool, particularly in gravel.

|

Whilst drum model DD-20 has proved its efficiency, particularly in gravel,

dewatering drum model DD-28

has been developed for mixtures with a high sand concentration or where it is required, to retain a maximum of fine sand.

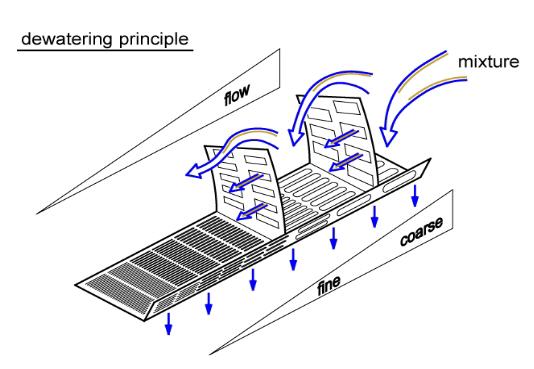

To achieve this, perforated and slotted mats with varying openings and perforated baffles are provided, and the mixture will be calmed before entering the drum to avoid turbulance. Where required the drum can be combined with an additional vibrating dewatering chute. Another option is a pump/cyclone-system to treat the waste water.

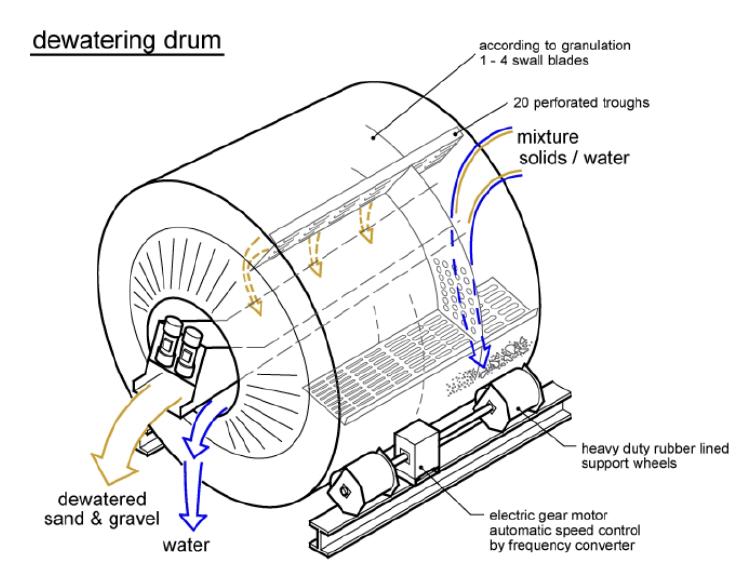

Operating principle:

The mixture slowly enters into the rear, lower section of the dewatering-drum. Coarser aggregate instantly settles in the area where there are perforated plates. Finer aggregate and particularly sand is flushed forward by the water and settles in the areas before. These are equipped with slotted mats, whereas the slots towards the drum front end become progressively more narrow.

|

Radially positioned, the Pressair dewatering drum has 20 troughs. During operation, the lower section is filled with a mixture of solids and water. While the drum slowly turns, the aggregate is raised out of the water and as the lifting continues, the water continuously escapes through the perforated or slotted plates. Having arrived at the top, the dewatered aggregate slides off the trough and falls on the vibrating chute which reaches into the drum at an angle of approximately 15°. This chute provides additional drying and delivers the aggregate onto a conveyor. The drum rests on heavy-duty rubber lined wheels and is powered by electric gear motors positioned on either side. The drum turning speed is automatically controlled in relation to the actual load.

Apart from sight inspections, the Pressair dewatering wheel requires no regular maintenance.

|

| detail: dewatering drum drive |

|

| aggregate after dewatering, 350 t/h |

|

|

Pressair dewatering drum 400 t/h with optional cyclone/screen system |

| Typ | mixture Kubikmeter/h | solids t/h | weight t/size | KW |

| DD-20 | 800 | 350 | 6,8 /D3,3x2,0 m | 11 |

| DD-28 | 900 | 400 | 8,5 /D3,3x2,8m | 15 |

Design protected. Version 2004. Performance data according to practical experience but not binding. Design subject to change.

Web: www.pressair.com